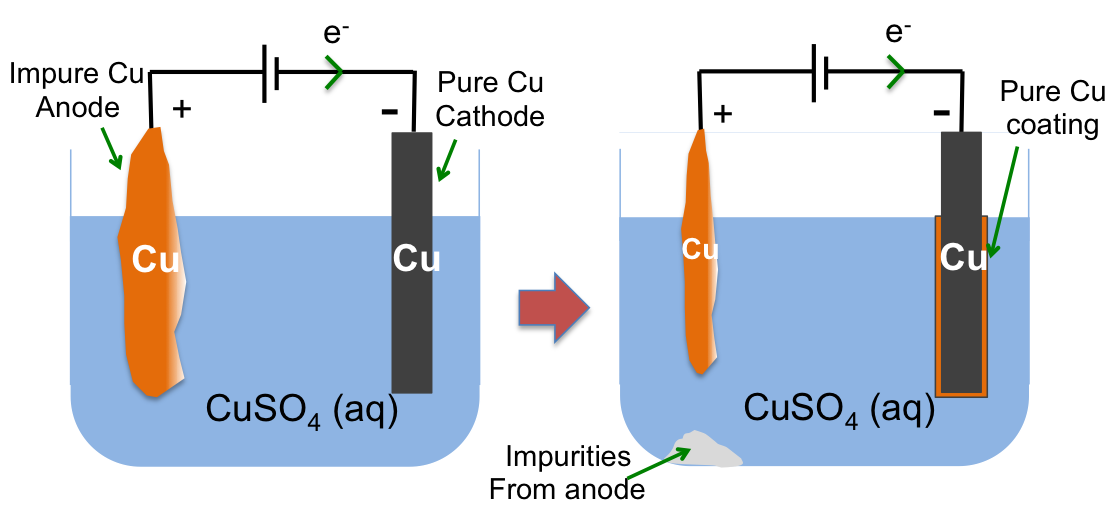

Electrolytic cell 4 in the earlier question is an example of the use of electrolysis to refine metals. Copper ore, which contains small amounts of other metals like Pt and Au, is the anode, while a piece of pure Cu is the cathode.

At the anode, Cu, which competes with H2O and SO42-, is preferentially oxidised to aqueous Cu2+ because it lies above H2O and SO42- in the electrochemical series and is more concentrated relative to the other two species (i.e., high number of Cu atoms in the electrode per unit volume as compared to the other two species in the electrolyte per unit volume).

Cu (s) →Cu2+ (aq) + 2e–

At the cathode, Cu2+, which competes with H2O, is preferentially reduced to Cu, as it is lower in the electrochemical series than H2O. Additionally, it is more concentrated relative to H2O.

Cu2+ (aq) + 2e– → Cu (s)

The overall redox reaction results in the coating of a layer of pure copper on the surface of the pure copper cathode:

Cu (s) → Cu (s)

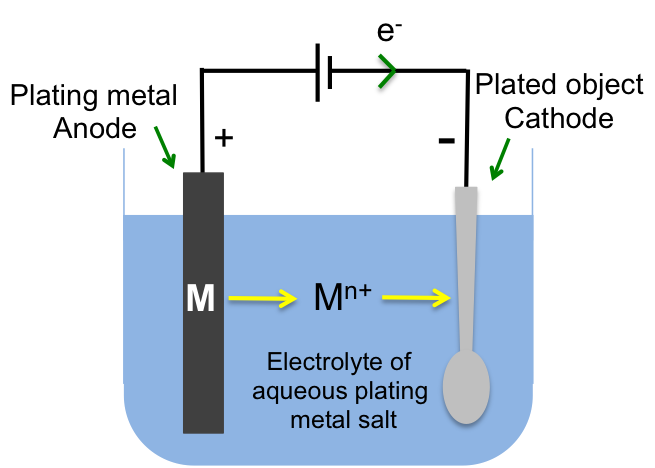

If we replace the anode with a pure metal, e.g. Ni, and the electrolyte with an aqueous salt of the metal, e.g., NiSO4, a layer of Ni will coat the cathode (see diagram below). This is the principle of electroplating.

Examples of electroplating are:

|

Plating Metal, M |

Plated object |

|

Ni, Cr |

Automotive parts, electrical appliances |

|

Sn |

Ornaments, jewelry |

|

Ag, Au, Cu |

Cutlery, ornaments, jewelry, electronic components |

next article: Applications of electrolysis: Extraction of metals

Previous article: Analysing reactions in an electrolytic cell

Content page of basic electrochemistry

Content page of Basic chemistry

Main content page